Screen Printing Custom T-shirts Abilene Can Be Fun For Everyone

Wiki Article

7 Simple Techniques For Screen Printing Custom T-shirts Abilene

Table of ContentsScreen Printing Custom T-shirts Abilene Fundamentals Explained9 Simple Techniques For Screen Printing Custom T-shirts AbileneScreen Printing Custom T-shirts Abilene Things To Know Before You Get ThisOur Screen Printing Custom T-shirts Abilene IdeasThe Buzz on Screen Printing Custom T-shirts AbileneThings about Screen Printing Custom T-shirts Abilene

No blending needed, remedies incredibly swiftly, expensive, ideal for comprehensive job. Combination of Diazo and SBQ, requires blending, overall cure time is less than Diazo, rate is lower than SBQ. The transparent acetate movie is positioned on the emulsion-coated mesh screen very carefully under a bright light which creates the solution to solidify and create.Subjecting the screen for a certain time will certainly solidify the uncovered areas of the screen, and the staying unhardened solution, if any kind of, will certainly be washed away to leave a clear imprint on the screen. The screen is after that dried out, and if there are any touch-ups needed, it will certainly be done by the printer to make the imprint as close to the initial layout as feasible.

The material to be printed is put flat on the printing board, and the display on top of the material in the preferred placement, prepared to be printed. In this action, the printed design will come to life. The display is lowered to the printing board. The preferred colour ink is included in the top of the display.

The ink presses through the open areas of the stencil and transfers on the underlying silk, subsequently publishing the layout on the product. The stencil will certainly have offered its function once all the things are printed. An unique cleaning liquid is made use of to eliminate the solution to recycle the mesh for creating brand-new stencils.

The 15-Second Trick For Screen Printing Custom T-shirts Abilene

There are six different types of screen printing processes. The most typical display printing strategy is spot colour screen printing.It is much less complex to use as contrasted to other screen printing methods. It can be an outstanding alternative for printing on t-shirts, coats, and hoodies. In halftone printing, solitary colours in slopes are printed. The whole process makes use of a solitary colour of ink, and this colour gets half-toned, resulting in a different color when checked out from a distance.

On top of that, it is a cost-effective technique given that just one colour of ink is used. Grayscale printing is an outstanding method of printing full-colour pictures as one colour grayscales or halftones. The print will look much more in-depth if the halftone has more dots. It is not a black and white technique; rather, it takes out the CMY or RGB or colour ranges only but in shades of grey.

Unknown Facts About Screen Printing Custom T-shirts Abilene

Duotone printing uses the mix of two halftones for publishing the exact same image with two colours. Initially, a black halftone is printed with black ink, and then a 2nd halftone is printed with colour ink. This technique resembles sepia-toned print in digital photography. It offers an advanced and artistic impact.

It includes the four standard colours cyan, magenta, yellow and black. These four colours are combined to create the needed colour tones. It can be done manually however ideally need to be done instantly for ideal outcomes. The simulated printing procedure incorporates the four-colour printing process with spot colour printing. Because this method works for both lighter and darker shades, it is functional and preferred with people looking to generate photorealistic print detail.

Some of these benefits include: One of the primary advantages of screen printing is its flexibility. Contrasted to various other printing approaches, screen printing can apply a hefty ink coverage, resulting in a durable style.

Some Known Incorrect Statements About Screen Printing Custom T-shirts Abilene

Screen printing is one of the most effective and fast printing methods once a display has actually been created. The display printing procedure is relatively straightforward, whether it is automated or done manually.

Customized display printing is a process that uses a mesh display to push ink in a fixed layout onto the material of your choice. Screen printing is prominent for personalized tee shirts, sweatshirts, jackets, and more. Custom screen printed tees or other screen-printed garments are the best means for businesses to enhance their brand name presence.

All about Screen Printing Custom T-shirts Abilene

The ink's longevity makes certain that prints endure repeated washing and put on, making it optimal for textiles like tee shirts, hoodies, and carryall. This technique works with a wide variety of surfaces, including materials, plastics, glass, timber, and steels. Its adaptability allows services and creators to apply designs to items like garments, advertising items, signage, and packaging.

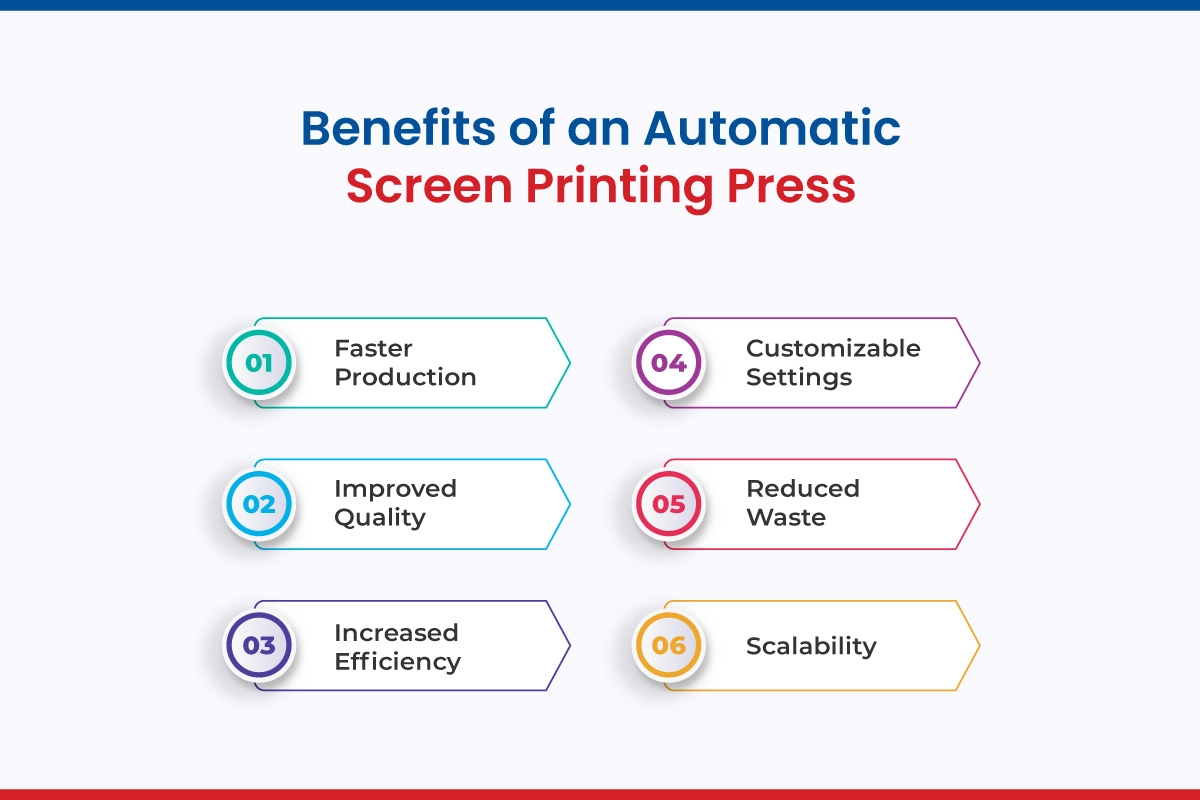

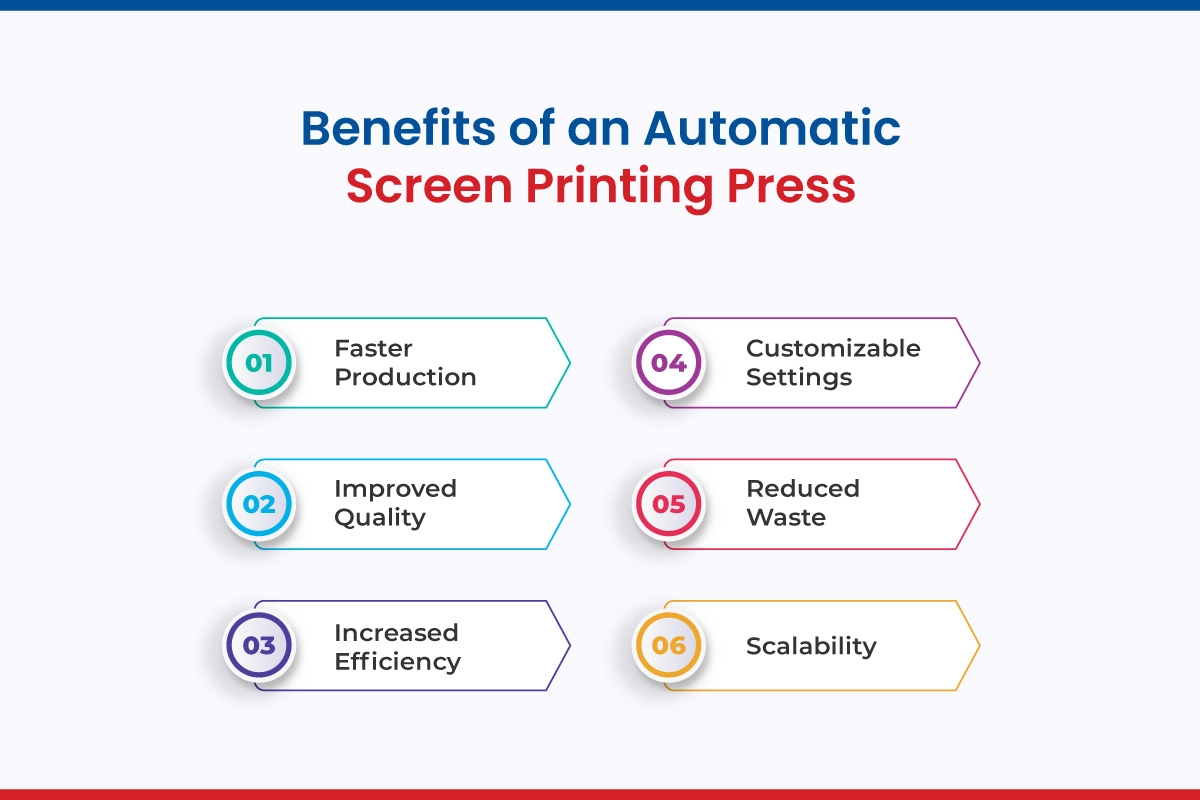

Modern automated display printing devices streamline the process, making it possible for higher manufacturing rates while preserving consistent top quality. Automation minimizes errors, guaranteeing every print is identical and up to expert criteria. Advancements like computer-to-screen (CTS) and direct-to-screen (DTS) technologies are revolutionizing the display printing procedure. These methods get rid of the demand for conventional film positives by electronically transferring screen printing layouts directly onto the display.

3 Easy Facts About Screen Printing Custom T-shirts Abilene Described

While rooted in tradition, display printing has actually accepted technical advancements to fulfill modern demands. Its combination of workmanship and advancement ensures it continues to be a top choice for imaginative and industrial printing jobs. Screen printing remains to be a reliable and functional printing technique, using lively colors and long lasting layouts that stand apart on a selection of materials.

For garment layout that calls for a high degree of vibrancy when printing on dark grounds, screen printing is still the ideal option.

per thing) are much faster. Thus greater volumes can be standardized utilizing screen printing quicker and more expense efficiently for larger orders. Display printing fits a large range of materials, including plastic, textile, stiff plastic, foam board, metal, glass and several others. The printer can create various products, such as banners, Tee shirts, hats, posters and wallpapers utilizing the very same screens.

Report this wiki page